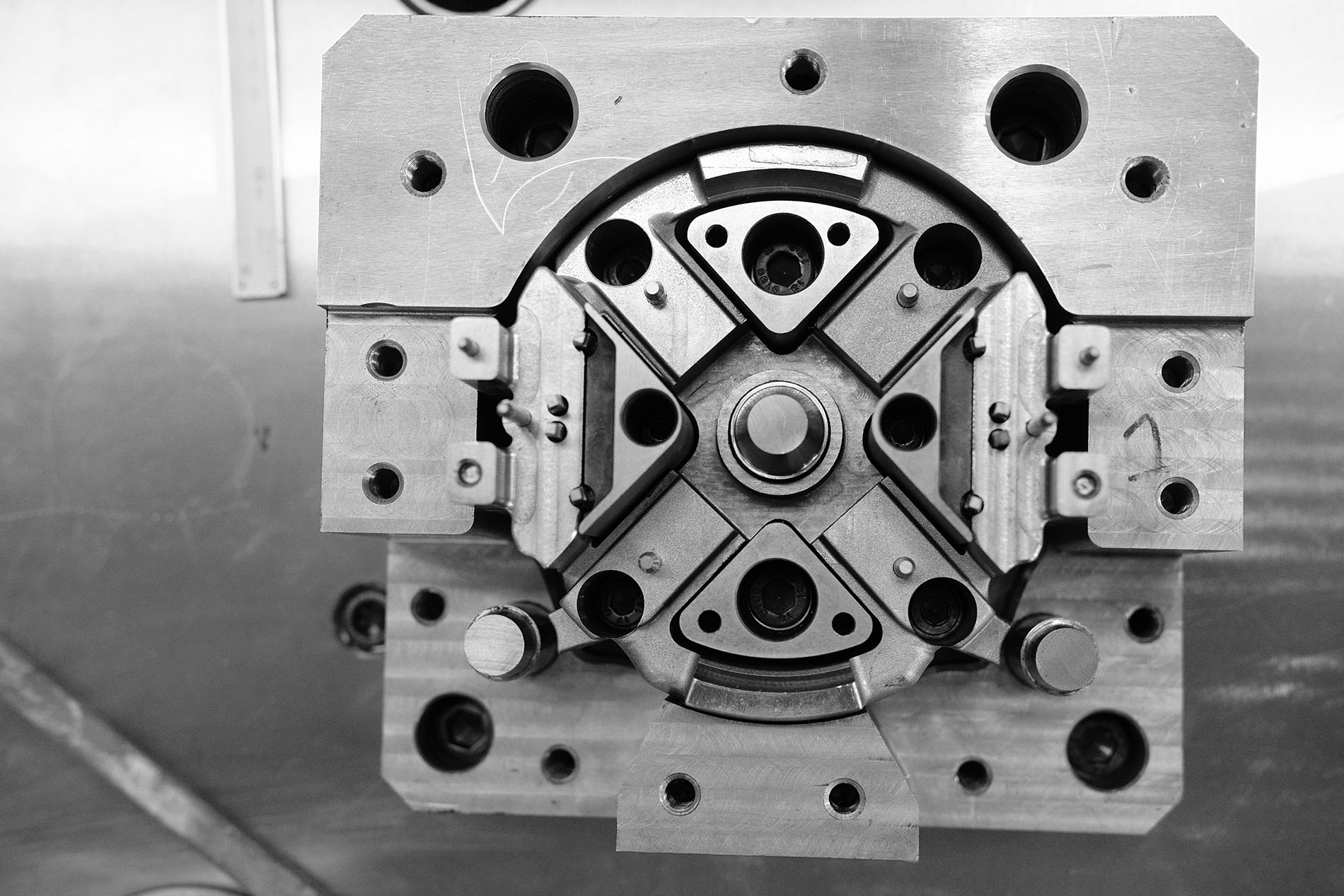

High Pressure Die Casting (HPDC)

High-pressure aluminium moulds are very demanding tools from a thermal point of view, which always requires a joint study between the manufacturer and the foundryman in order to obtain the best possible results.

As the injection pressures and working temperatures are very high, the correct sizing of the moulds, the steel to be used and the heat treatment are fundamental points that must be defined and coordinated for the success of the entire process.

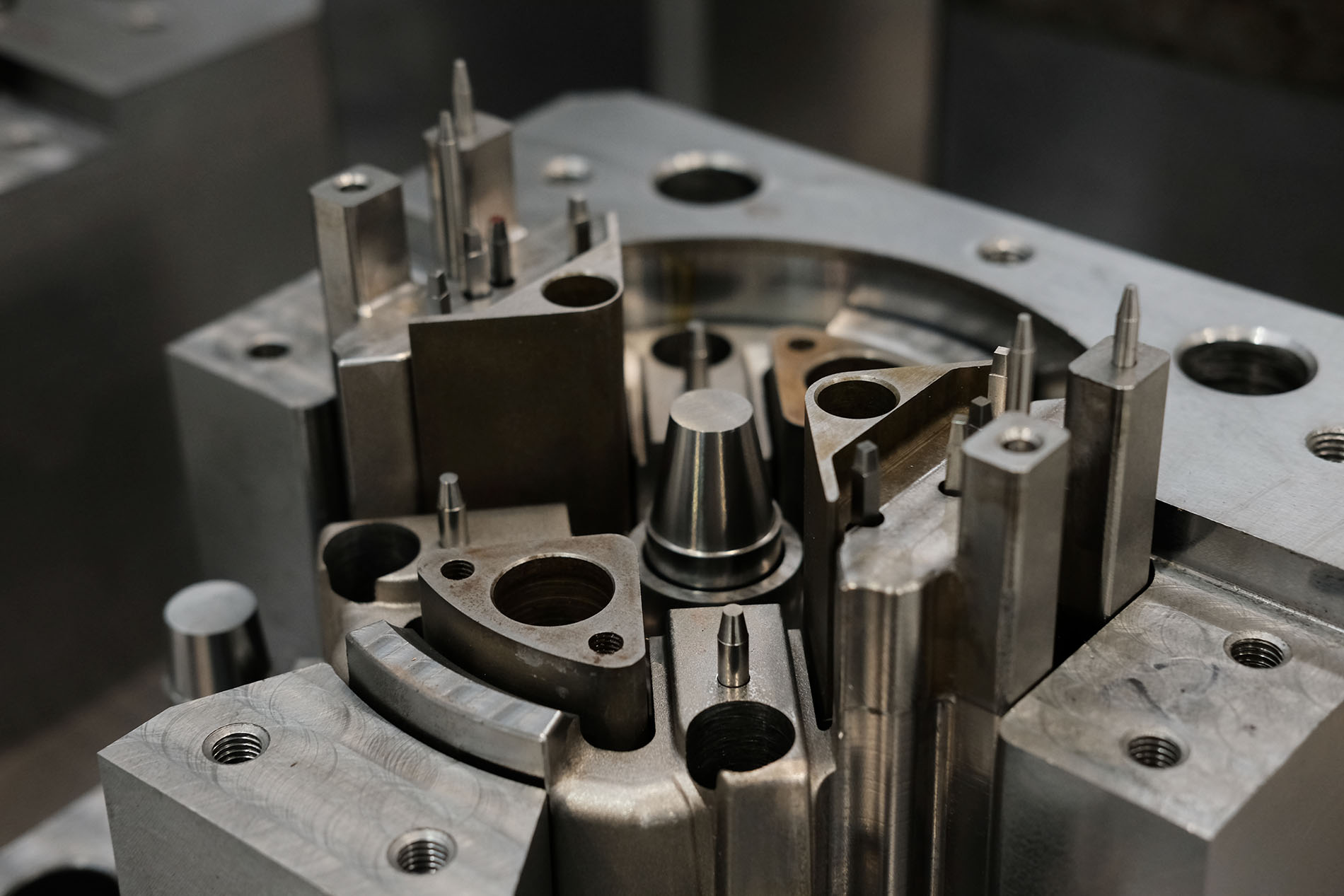

Low pressure (LPDC)

Low pressure injection moulds require the same attention to quality as HPDC moulds. However, the parts obtained by this process have a higher density and are more resistant to shock and vibration, so they are usually used for parts that require greater resistance, such as car chassis and wheel rims.